LAS ZIRH – BYG Partnership

The World’s Leading Tire Protection Chain Manufacturer LAS ZIRH Joins Forces with BYG, a Leader in Direct Spare Parts Manufacturing and Distribution.

BYG was founded in 1967 as a family-owned company. It manufactures and distributes direct replacement parts for all major OEM brands operating in the mining, quarrying, and construction sectors. Initially specializing in fastening elements for infrastructure and construction machinery, BYG has gradually expanded its product range to include wear parts and various spare parts. Today, BYG is one of the most important national and international references in the production and distribution of spare parts for mining and infrastructure equipment.

BYG stands out with its unwavering commitment to innovation throughout its history. Customer and market needs have always been BYG’s top priority. Thanks to proprietary technologies developed by its own engineering department and R&D quality, BYG produces innovative products worldwide.

To serve its growing customer base in more than 100 countries, BYG collaborates with regional distributors.

Beyond guaranteeing product quality, BYG’s in-house engineering team continuously develops and improves the FUTURA and BYG product lines. The research and development department of BYG utilizes the industry’s most advanced technologies. Every day, BYG engineers design new products based on customer demands and feedback. BYG’s goal is to design and manufacture high-performance and efficient products for every application.

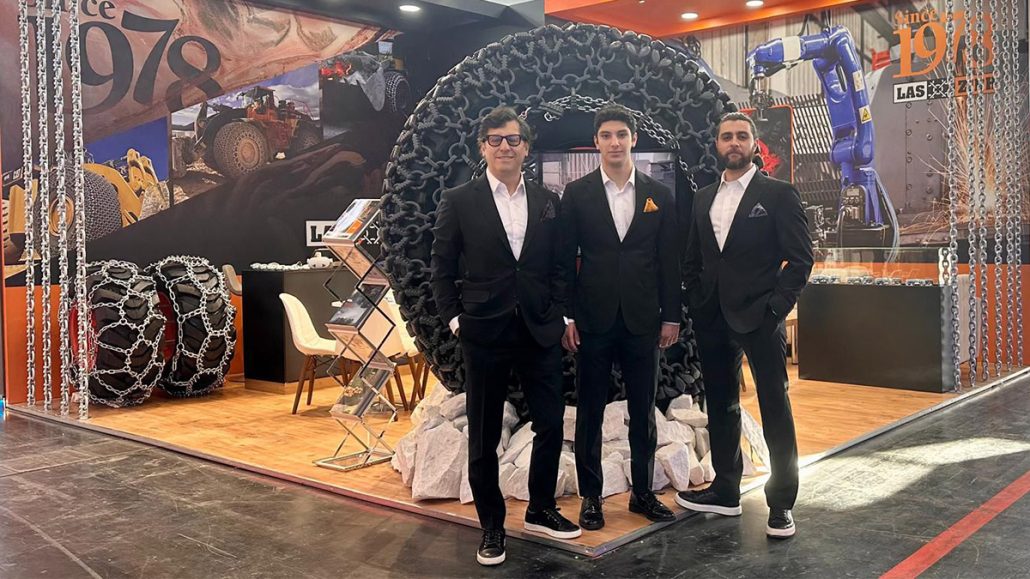

Afyon Marble Fair (ALZ) 2025

One of Turkey’s largest marble industry events, the AFYON MARBLE FAIR (ALZ), was held between June 18–21, 2025, and we proudly took our place at this prestigious event. We had the opportunity to share the latest innovations in our tire protection chains and explore new business opportunities with visitors and guests from across Turkey and around the world.

Bauma Munich 2025

One of the world’s largest international trade fairs for construction and mining machinery and equipment, BAUMA MUNICH 2025, took place between April 7–13, and we were proud to take our place at this prestigious event. We had the opportunity to share the latest innovations in our tire protection chains and explore new business opportunities with visitors and guests from all around the world.

İzmir Marble Fair 2025

One of Turkey’s largest marble industry events, İZMİR MARBLE FAIR, took place between April 9–12, 2025, and we proudly took our place at this prestigious event. We had the opportunity to share the latest innovations in our tire protection chains and explore new business opportunities with visitors and guests from across Turkey and around the world.

Emerging Technologies in Tire Protection Chains

Tire protection chains are essential equipment for heavy-duty machinery and vehicles operating in challenging terrain. With advances in technology, these chains have been enhanced with smart systems that significantly improve both performance and safety. In this article, we explore the innovations brought by smart tire protection chain systems and the future trends shaping this field.

What Are Smart Tire Protection Chain Systems?

Traditional tire protection chains are known for their mechanical structures, but today’s systems are enhanced with sensors and automation technologies, making them smarter. These systems collect real-time data to alert operators and help prevent potential failures.

Sensor-Integrated Chain Technology

Strain and Wear Detection Sensors

Modern tire protection chains are equipped with micro-sensors that monitor strain and wear continuously. These sensors help identify potential problems such as fatigue or loosening early. This allows for better maintenance scheduling and prevents dangerous failures.

Real-Time Monitoring and Alert Systems

Sensor data is transmitted to a central control panel or mobile device. With real-time monitoring, operators receive constant updates about chain condition. Alerts for excessive tension or slack are sent immediately, minimizing safety risks and downtime.

Adaptive Chain Structures

Automatic Tension Adjustment

Next-generation tire chain systems feature automatic tensioning mechanisms. These systems adjust the chain’s tightness based on speed and terrain, preventing tire damage and enhancing driving stability.

Self-Adjusting to Environmental Conditions

Smart chains detect temperature, humidity, and ground type to optimize performance. On muddy terrain, for example, the contact surface may expand to increase grip. These systems boost efficiency and operational safety while extending chain lifespan.

Industry 4.0 Integration in Chain Technologies

The rise of Industry 4.0 has also impacted tire protection chain technologies. Internet of Things (IoT) and digital twin concepts enable smarter and more efficient chains.

IoT-Enabled Chains

Remote Monitoring and Data Sharing

IoT-based chain systems transmit chain data wirelessly to the central office or cloud. This allows fleet managers to monitor machine status without being on-site. All maintenance and performance records are archived digitally, enabling faster, data-driven decisions.

Big Data and Predictive Maintenance

Sensor data is analyzed through big data systems to predict failures before they occur. Predictive maintenance reduces downtime and costs while supporting smart decision-making. The system can also suggest optimal chains based on past performance.

Digital Twin and Simulation Applications

Lifecycle Prediction and Performance Modeling

Digital twin technology simulates the chain’s performance over its entire lifecycle. It estimates when maintenance or replacement will be needed, leading to more accurate planning and extended service life for tire protection chains.

Simulation-Based Design Development

Simulations allow testing of different materials and designs. This leads to stronger, lighter chain models. Chain manufacturers can deliver more efficient products and integrate operator feedback into development.

The Future of Tire Protection Chain Technologies

In the near future, tire protection chains will become even more sustainable and intelligent. New materials and artificial intelligence integration will play key roles in this transformation.

Sustainable and Lightweight Material Development

Recyclable Composite Materials

New chain materials are being designed with environmental sustainability in mind. Composite-based chains are lighter, more flexible, and offer long-lasting performance without harming the environment—ideal for sustainable mining and construction.

Energy-Efficient Designs

Modern chain designs aim to reduce fuel consumption. Using lightweight alloys instead of steel lowers rolling resistance and reduces engine load. Energy-efficient chain designs offer long-term cost savings and reduced emissions.

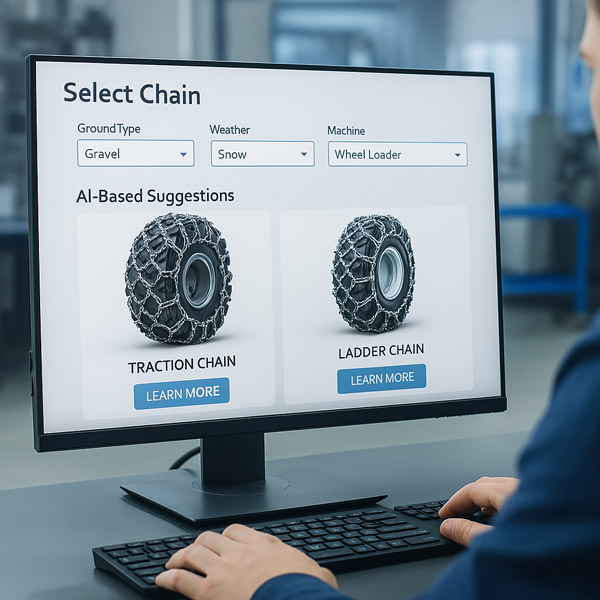

AI-Powered Chain Selection Systems

Machine Learning-Based Product Matching

AI algorithms recommend the best tire protection chain model based on machine type, terrain, and weather. These systems use past usage data to optimize performance and safety, while reducing human error.

Decision Support Algorithms and Automation

Advanced selection platforms analyze numerous variables to provide decision support. Users can place orders or plan maintenance based on system suggestions. These platforms may also integrate with automated inventory systems, optimizing logistics processes.

Comparison of Steel and Alloy Tire Protection Chains

The use of tire protection chains in heavy-duty machinery is critical for boosting performance and ensuring workplace safety. The material from which these chains are manufactured makes a significant difference in terms of lifespan and operational efficiency. Choosing the right material based on the intended use can reduce costs and support operational continuity. In this article, we’ll compare steel and alloy tire chains in terms of durability, cost, application areas, and safety.

What Are Tire Protection Chains and Why Are They Used?

Tire protection chains are essential equipment that help heavy-duty machinery operate safely and efficiently in harsh conditions. They protect against wear while directly impacting machine performance. Chain selection should consider the working environment and terrain conditions.

Main Functions of Tire Protection Chains

These chains not only protect tires from physical damage but also improve traction, reducing operational risks. They play a vital role in both safety and cost control.

Reducing Wear and Extending Tire Life

Tire protection chains safeguard tires from abrasive ground elements like sharp rocks, mining debris, and metal fragments. By reducing these impacts, the chains extend tire life, support operational continuity, and prevent downtime from unexpected tire replacements.

Enhancing Operational Safety

Chains improve ground grip, reducing the risk of slippage. Especially on sloped or muddy terrain, tire protection chains are vital for both operator and environmental safety. They prevent loss of control, ensuring machine stability and minimizing workplace accidents.

In Which Sectors Are They Used?

Choosing the right material and structure based on the sector significantly enhances efficiency and equipment life.

Mining and Quarrying

One of the most common areas of use is underground and open-pit mining. Steel tire protection chains offer extra resistance to impact and sharp surfaces, making them ideal for such high-risk environments.

Construction and Infrastructure Projects

Construction machinery must operate on various terrain types. Chains enhance traction, prevent skidding on concrete or asphalt, and reduce downtime, contributing to safer and more efficient operations.

Forestry and Agriculture

In sectors where machines operate on soft, slippery surfaces, alloy tire protection chains are preferred for their flexibility and light weight. They are ideal for environments with constantly changing terrain, offering balance and agility.

Steel vs. Alloy Chains: Material Characteristics

Steel and alloy chains differ significantly in structure and performance, especially when exposed to varying operational conditions. Choosing the right material is critical for operational continuity and cost-efficiency.

Structural Features of Steel Chains

Steel chains offer high durability and hardness, making them suitable for machines under heavy load. They are resistant to high temperatures and sharp surfaces, ensuring long-term use.

Hardness and Wear Resistance

Steel tire protection chains provide excellent defense against sharp rocks. Their surface strength protects tires from direct impact, increasing both tire life and operational safety.

Impact Absorption

Due to their dense structure, steel chains absorb sudden impacts effectively. This improves machine stability and contributes indirectly to operator safety, especially in tough conditions like rockfalls.

Structural Features of Alloy Chains

Alloy tire protection chains are known for their lightness and flexibility. They generate less surface friction, offering better maneuverability and performance in soft or muddy terrain.

Flexibility and Lightweight Design

Alloy chains do not restrict machine movement and are especially advantageous in confined areas. Their lighter weight reduces fuel consumption and allows for easier installation. They are ideal for short-term or seasonal operations.

Corrosion Resistance

Alloy chains generally offer better corrosion resistance. In humid or chemically exposed environments, they outperform steel chains in longevity and reduce maintenance frequency.

Performance Comparison Based on Application

The performance of chain types varies greatly depending on their application environment. Selection should factor in terrain, machine type, and operational intensity.

Effectiveness by Terrain Type

Steel and alloy chains perform differently depending on the ground they are used on. Choosing the right type improves traction and reduces tire wear.

Rocky and Metal-Rich Grounds

Steel chains perform best on hard, abrasive surfaces. Their high hardness provides resistance to impact and longevity, making them ideal for mining and quarry operations.

Muddy and Soft Grounds

Alloy chains offer better traction in mud and soft terrain. They don’t dig into the ground, making them suitable for agriculture. Their flexibility reduces slipping and improves control.

Suitability by Machine Type

Different machines have unique weight and movement dynamics, which influence the choice of chain.

Loaders and Excavators

For machines that handle heavy loads on rough terrain, steel chains provide better durability and lower replacement frequency. They are especially suited for open-field operations.

Underground Transport Vehicles

In tight and low-clearance areas, alloy chains offer better maneuverability and smoother operation. They also produce less noise than steel chains.

Cost and Long-Term Investment Analysis

Initial price isn’t the only factor; long-term durability and maintenance costs should also be considered. Steel and alloy chains represent different investment profiles.

Initial Purchase Costs

While steel chains typically cost more upfront, their longer life and resistance to wear may lead to lower total ownership cost over time.

Steel Chain Cost

Steel chains require higher initial investment but can last longer under tough conditions. Their reduced need for frequent replacement lowers both downtime and maintenance costs, making them ideal for machines with intense usage.

Alloy Chain Cost

Alloy chains are more affordable initially, making them a good option for short-term or seasonal use. However, they may need more frequent replacement, increasing long-term costs if not properly maintained.

Maintenance and Repair Considerations

Maintenance frequency and repair needs depend largely on material type. These affect the overall cost and operational efficiency of the chain.

Rusting and Breakage Risks

Steel chains are more prone to rust and require regular cleaning and lubrication. Alloy tire protection chains offer better resistance to corrosion but are more susceptible to breakage under heavy load, requiring frequent inspections.

Service Life and Recyclability

Both chain types are made from recyclable materials. However, steel chains can often be repurposed after their initial service life. With proper use and care, their lifespan can double, reducing long-term expenses.

Safety and Operational Advantages

Preventing workplace accidents and ensuring continuous operations are direct benefits of selecting the right chain. Machine control and workplace safety are highly dependent on chain quality.

How Chain Selection Impacts Safety

Chains don’t just protect tires; they also improve machine grip, which supports a safe work environment in the long run.

Reducing Slip Risks

Tire protection chains enhance traction on slippery surfaces, reducing slip and skid risks. This is especially critical in mines and sloped terrain, improving both operator and nearby personnel safety.

Braking and Maneuverability

Alloy chains enable smoother braking and direction changes due to their lighter build. This is important in restricted workspaces where responsive control is needed.

Role in Ensuring Operational Continuity

Continuous operations depend not just on machines but on durable equipment. Chains provide added protection that helps avoid unexpected failures.

Reducing Downtime

Tire protection chains help prevent blowouts and surface cracks, which are major causes of unexpected downtime. Fewer interruptions mean higher productivity and more consistent project timelines.

Optimizing Maintenance Intervals

Using the right chain extends tire maintenance intervals, reducing labor and service costs. It also contributes to a safer, more comfortable work environment for operators.

Choosing the Right Chain for the Job

When choosing between steel and alloy chains, consider not only price but also field conditions, machine type, and project duration. Selecting the most efficient option improves overall business performance.

Comparison Summary

Each chain type offers unique benefits. Durability, weight, cost, and area of use are key factors when comparing. Steel chains excel in long-term, harsh environments, while alloy chains suit short-term, confined operations.

Durability – Weight – Cost – Application

Steel chains are favored for their long service life and durability, while alloy chains offer flexibility and lightness. The choice depends on terrain and machine workload.

Expert Advice and Selection Tips

There’s no one-size-fits-all solution. However, with proper analysis, the most efficient and economical result can be achieved.

Considering Site Conditions

Before selecting a chain, evaluate site topography, climate, and ground structure. This ensures tire protection chains perform optimally and prevents unnecessary expenses.

Suitability to Machine and Load Type

For heavy-load machines, durability is key—steel chains are preferred. For agile, frequently maneuvering machines, alloy chains are more suitable. Matching the chain type to the machine prolongs lifespan and improves operational safety.

The Importance of Using Tire Protective Chains Usage in Underground Mining

Underground mining is defined by its harsh working conditions and high-risk factors. In this environment, tire protection chains play a critical role in enhancing safety and ensuring operational efficiency. Using the right chain helps optimize machine performance while minimizing workplace accidents and costs.

Why Are Tire Protection Chains Important in Underground Mining?

Challenging Conditions of Underground Environments

Underground mines are characterized by narrow tunnels, low visibility, and slippery surfaces. These conditions threaten the stability and safety of heavy machinery. Tire protection chains allow equipment to operate more safely and efficiently under such extreme circumstances.

Hazards Faced by Machine Tires

Tires used in underground mining are constantly exposed to sharp rocks, metal debris, and other abrasive materials. This leads to rapid wear and potential damage. Tire protection chains shield tires against these threats, reducing breakdowns and downtime.

Safety Advantages Provided by Tire Chains

Reducing the Risk of Slipping and Skidding

Mine surfaces are often wet and slippery, increasing the risk of skidding. Tire protection chains improve grip on the ground, minimizing these risks and helping operators maintain control in dangerous conditions.

Enhancing Operator Safety

Unstable machines pose serious threats to operators. Tire protection chains contribute to better machine balance, improving safety and comfort for operators. This helps prevent workplace accidents.

Additional Protection Against Fire and Explosion Risks

Overheating of tires in underground environments can increase the risk of fires and explosions. Tire protection chains help prevent excessive heat buildup, contributing to a safer work environment.

Impact on Efficiency and Cost Management

Extending Tire Lifespan and Reducing Wear

Frequent tire replacements in underground mining result in time loss and high maintenance costs. Tire protection chains reduce wear, extend tire life, and help cut down on replacement expenses.

Reducing Machine Downtime

Tire-related issues can halt machine operation and disrupt production. Tire protection chains reduce the likelihood of tire damage, minimizing downtime and ensuring continuous workflow.

Supporting Continuity and Production Planning

Unexpected stoppages can lead to missed targets in production planning. Tire protection chains support uninterrupted machine operation, contributing to production reliability and strategic planning.

How to Choose the Right Chain for Underground Mining Equipment?

Performance Comparison of Chain Types

Steel Chains

Steel chains are known for their durability and long lifespan. Among tire protection chains, they are the most commonly used type and deliver outstanding performance in demanding terrain conditions.

Lightweight Alloy Chains

Alloy chains enhance machine maneuverability due to their lighter weight. These tire protection chains are often preferred for their flexibility and ease of use.

High-Traction and Anti-Slip Models

Chains with dense patterns provide superior grip on slippery surfaces. These types of tire protection chains are ideal for users prioritizing safety and stability.

Selecting Chains Based on Machine Type and Ground Conditions

Each machine and surface type requires specific chain features. When choosing tire protection chains, it’s important to consider the machine model, working conditions, and ground type.

Maintenance, Installation, and Long-Term Use Tips

Installation Techniques Suitable for Underground Environments

Proper installation directly affects the performance and durability of tire protection chains. Secure and precise installation ensures safe and efficient machine operation underground.

Periodic Inspection and Cleaning of Chains

Dirt and debris buildup in underground environments can reduce the effectiveness of chains. Regular cleaning and inspection of tire protection chains are essential for long-lasting and high-performance use. It’s also important to check for early warning signs like loosening, cracking, or deformation.

Using Chains for Safe and Efficient Operations in Underground Mining

In high-risk sectors like underground mining, tire protection chains are an essential solution for improving safety and ensuring operational continuity. Proper chain selection, regular maintenance, and correct installation help maximize machine performance, reduce accidents, and lower overall costs. For machines operating in underground mines, these chains are not just a preference but a strategic necessity for sustainable business operations.

Tire Protection Chains and Their Role in Work Safety

Heavy-duty machinery operates in harsh terrains where safety is a top priority. Tire protection chains enhance safety by reducing the risk of slippage and increasing tire durability. Using the right tire protection chains for machines operating on slippery and uneven surfaces helps prevent workplace accidents. This article explores the impact of tire protection chains on workplace safety and their sector-specific applications.

What Are Tire Protection Chains and Why Are They Important?

How Tire Protection Chains Work

Tire protection chains shield heavy machinery tires from sharp rocks, slippery surfaces, and other external factors, improving overall safety. These chains cover the tire surface, preventing excessive wear and enhancing machine stability. By protecting tires from damage, they extend operational time and improve efficiency. In industries such as mining and construction, preventing premature tire wear offers significant cost benefits.

Key Benefits of Tire Protection Chains for Heavy Machinery

These chains increase machine stability, prevent tire blowouts, and create a safer working environment. Additionally, they extend tire lifespan, reduce maintenance costs, and enhance operational efficiency. With improved traction, operators can work more comfortably and with better control. As a result, workplace accidents are reduced, and workflow remains uninterrupted.

How Do Tire Protection Chains Improve Workplace Safety?

Reducing Slippage and Accident Risks

Providing Better Traction on Slippery Surfaces

In muddy, snowy, or rocky terrains, tire protection chains offer additional traction, preventing machinery from slipping. This is especially critical for machines operating in extreme conditions. By ensuring stability on rough terrains, these chains help operators maintain control. This enhances workplace safety and supports overall productivity.

Enhancing Braking and Turning Capabilities

Chains added to tires improve braking stability and prevent loss of control in turns. This enhances operator safety and machine maneuverability. In heavy-duty vehicles carrying substantial loads, reduced braking distances help prevent unexpected accidents. Strong traction allows machines to move efficiently within worksites.

Preventing Tire Damage to Enhance Safety

Minimizing Wear and Punctures for Continuous Operation

Tire protection chains protect tires in rock quarries and mining areas where sharp objects pose a risk. This ensures uninterrupted operations and prevents unexpected downtime. If machinery tires are damaged, work may halt, increasing costs. Chains help prevent these disruptions, allowing businesses to maintain efficiency.

Preventing Accidents Due to Tire Blowouts

Tire blowouts in heavy machinery can lead to severe accidents. Chains prevent such incidents, improving workplace safety. Particularly in high-speed or heavy-load operations, a blown tire can result in serious injuries. Thus, using the correct chains plays a crucial role in workplace safety.

The Importance of Tire Protection Chains in Different Industries

Workplace Safety in Mining and Quarries

In rocky and debris-filled terrains, tire protection chains prevent machinery from slipping and protect tires from damage, ensuring a safer work environment. In the mining sector, they help reduce workplace accidents. Keeping machinery operational in mining sites is essential. Chains prevent sudden stops and malfunctions, increasing safety and efficiency.

Safety in Construction and Infrastructure Projects

On construction sites, heavy machinery constantly carries heavy loads. Chains help these machines remain stable, reducing the risk of tipping and slipping. Falls, slips, and rollovers are among the most common accidents on construction sites. Chains provide a firm grip on the ground, minimizing these risks.

Safety in Agriculture and Forestry

For machines operating in forests or muddy agricultural fields, chains prevent them from getting stuck, ensuring safer and more efficient work. This improves operational productivity in agriculture and forestry. In areas with unstable soil conditions, chains provide stability, preventing machine damage. Especially in rainy conditions, they prevent skidding, protecting tractors and forestry equipment from accidents.

Conclusion: The Importance of Tire Protection Chains for Workplace Safety

To ensure heavy machinery operates safely, tire protection chains are essential. With the right chain selection and regular maintenance, workplace accidents can be prevented, operational efficiency can be improved, and machine lifespan can be extended. Establishing a safer work environment benefits both worker safety and operational productivity. Chains reduce risks while ensuring uninterrupted workflow in industrial environments.

Tire Protection Chain Buying Guide

For heavy-duty machinery, tire protection chains play a critical role in extending tire lifespan and enhancing workplace safety in harsh terrain conditions. Choosing the wrong chain can reduce machine efficiency and lead to unnecessary costs. In this guide, we will explore how to select the best tire protection chain, what factors to consider, and the key advantages of using these chains.

What Are Tire Protection Chains and Why Are They Necessary?

Tire protection chains are specially designed steel chain systems that shield machine tires from sharp rocks, metal debris, and other abrasive materials. Particularly in industries such as mining, quarries, and construction, these chains help prevent excessive wear and reduce maintenance costs while improving tire durability.

How Do Tire Protection Chains Work?

These chains create a protective barrier over the tire surface, preventing impact damage and surface abrasions. Additionally, they improve tire traction, ensuring better machine performance and reducing the risk of slippage.

Advantages of Using Chains for Heavy-Duty Machinery

Tire protection chains not only enhance durability but also improve workplace safety by minimizing operational risks. Especially on steep slopes, muddy, or slippery terrain, these chains prevent machinery from sliding, ensuring a safer working environment.

What to Consider When Choosing a Tire Protection Chain?

Types of Chains and Their Applications

Steel Chains

High-durability steel chains are widely used in heavy industry machinery. They last longer on abrasive surfaces and provide maximum protection against impacts.

Alloy and Special Coated Chains

Alloy chains, which are lighter yet strong, are preferred in environments requiring flexibility and longevity. Corrosion-resistant coatings offer long-term usability.

Chain Patterns and Terrain-Specific Selection

The design of the chain surface directly affects tire grip. Specially designed patterns for snowy, muddy, or rocky terrain enable more stable machine performance.

How to Determine the Right Chain Size?

Matching Chain Size to Tire Dimensions

Each tire protection chain is designed for a specific tire diameter and width. Therefore, it is essential to consider the manufacturer’s recommended compatibility specifications when selecting a chain.

Common Mistakes in Chain Measurement

Incorrect measurements can result in chains being too loose or too tight. This can cause uneven pressure on the tire and eventually lead to tire damage over time.

Which Industries Require Tire Protection Chains?

Mining and Quarry Applications

Chains used in these sectors must have extremely high durability. Especially in environments with heavy rock and metal debris, heavy-duty chains that prevent tire punctures are preferred.

Construction and Infrastructure Projects

Chains used in construction machinery must have a more flexible structure and ensure maximum traction across different surfaces. Thin, tightly woven chains are particularly recommended for concrete and hard surfaces.

Forestry and Agricultural Applications

In the forestry and agriculture sectors, chains must perform well in mud, soil, and soft surfaces. Anti-slip models are especially effective in these conditions.

Key Considerations When Purchasing a Tire Protection Chain

Choosing a Reliable Supplier

Characteristics of a Trustworthy Supplier

A quality tire protection chain provider should offer warranty coverage, after-sales support, and spare parts availability.

Warranty and After-Sales Support Services

Since tire chains are considered a long-term investment, manufacturers should provide a minimum 2-year warranty and after-sales maintenance services.

Maintaining a Balance Between Price and Quality

Risks of Low-Quality Chains

Cheap chains tend to wear out quickly, break easily, and potentially damage tires. Therefore, durable and certified products should be chosen.

Long-Term Cost Analysis

Although high-quality chains may seem costly at first, they last longer, reducing replacement and maintenance costs, making them more cost-effective in the long run.

Installation and Maintenance of Tire Protection Chains

Key Considerations for Proper Chain Installation

Improper installation can lead to uneven wear and tire surface damage. Chain installation should follow the manufacturer’s guidelines and maintain proper tension.

Maintenance Tips to Extend Chain Lifespan

Chains should be regularly cleaned, lubricated, and protected against rust. Periodic inspections should be conducted to replace worn-out sections and ensure long-lasting durability.

Conclusion: Enhancing Safety and Performance with the Right Chain Selection

Selecting the right tire protection chain is essential for ensuring machine safety and efficiency. By choosing high-quality materials, the correct size, and proper installation, you can boost machine performance and extend tire lifespan.

![]()

Hakkı İleri Cad. No: 54 Hadımköy 34555 Arnavutköy İstanbul Türkiye

+90 212 771 44 10

info@laszirh.com